Table of Contents

Asphalt Shingle Roofing systems: What You Should Know

When was the last time you took a good look at your roof? For most homeowners, the answer is typical: “Not recently.” As a roofing contractor with decades of experience in the industry, we find that roofs don’t get much attention until there is a problem. We typically experience calls when some shingles have been blown off, or they have been impacted by storm damage , or a leak develops due to an ice dam or missing shingles. But what if I told you that you could prevent these issues before they even start?

Based in Colorado, the majority of residential and multi-family roofs are made up of asphalt shingles. They are also used from time to time in commercial roofing. Because they are affordable and fairly durable, they are a common roof replacement choice. So, learning about your asphalt shingle roof makes sense. Just like any other system in your home, your roof needs routine care, and that involves having a clear understanding of the system and its needs.

We want to help you understand everything you need to know about this common roof system to show how proactive learning can save you from the headaches and repair bills that an unmaintained roof can cause. By understanding the basics of your asphalt shingle roof, you can be better prepared to maintain this important defense mechanism against Mother Nature’s severe weather!

What are asphalt shingles made of?

Asphalt shingles are made through a multi-step process and consist of an organic felt or fiberglass base covered with an asphalt coating covered in mineral granules.

The shingle-making process

The shingle manufacturing process starts with the creation of an organic felt or fiberglass mat. This mat then passes through a saturation tank, where it is coated with hot asphalt. This step is crucial as it creates the waterproof barrier of your shingles.

While the asphalt-coated mat is still hot and tacky, ceramic-coated mineral granules are embedded onto the top surface of the shingles. These granules are what you see when you look at an asphalt shingle roof. In addition to protecting the shingle from UV rays and adding fire resistance, they also allow for color customization, helping blend your roof with your exterior color palette.

The shingle then goes through a cooling process, where it hardens and the granules set. Once cooled, the large sheet of material is cut into individual shingles in the desired shape and size.

The back of the shingle is often coated with a fine mineral powder that helps prevent them from sticking together in their packaging and during transport. A strip of thermally activated sealant may be applied to each shingle. This sealant is a major factor in the wind resistance of your asphalt shingle roof, as it helps the shingles bond together once installed on a roof and exposed to the heat of the sun.

Finally, the finished shingles are bundled and packaged for shipping to distributors for installation across the nation.

This process combines durability with cost-effectiveness, making asphalt shingles a popular option for residential and commercial roofing applications alike. Asphalt shingles provide a great balance of affordability, longevity, and a fairly straightforward installation process.

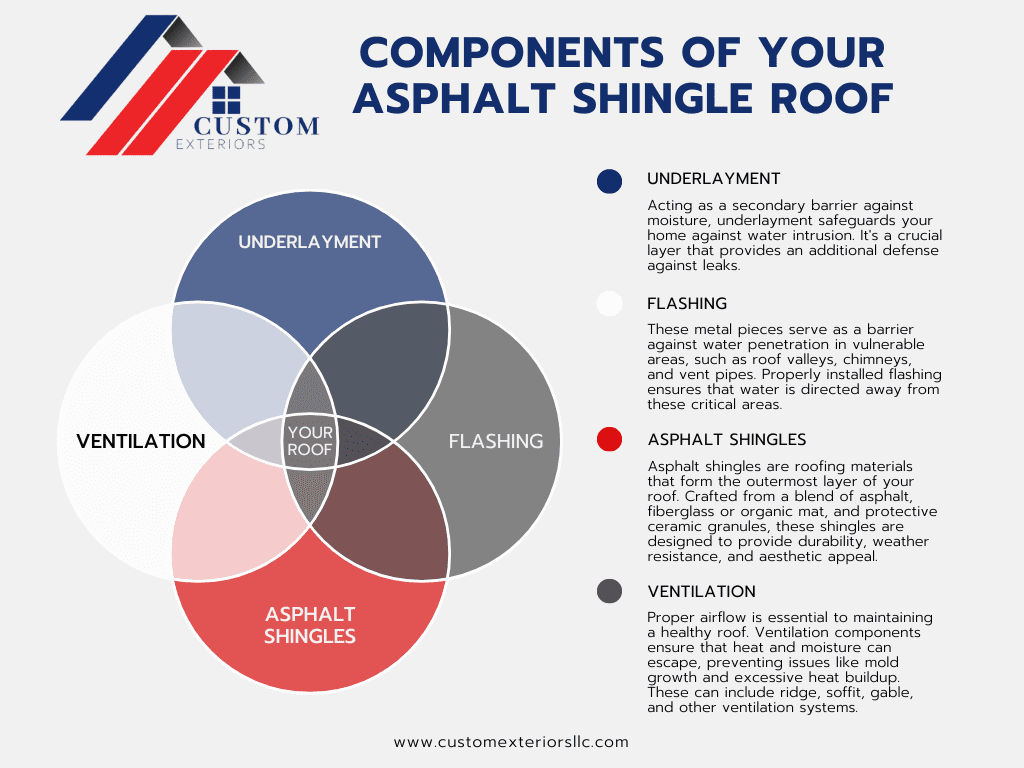

the components that make up an asphalt shingle roof

Your asphalt shingle roofing system has a lot of different roof components. By understanding how an asphalt shingle roofing system is designed, you can help keep it in good condition and prevent maintenance-related roofing issues.

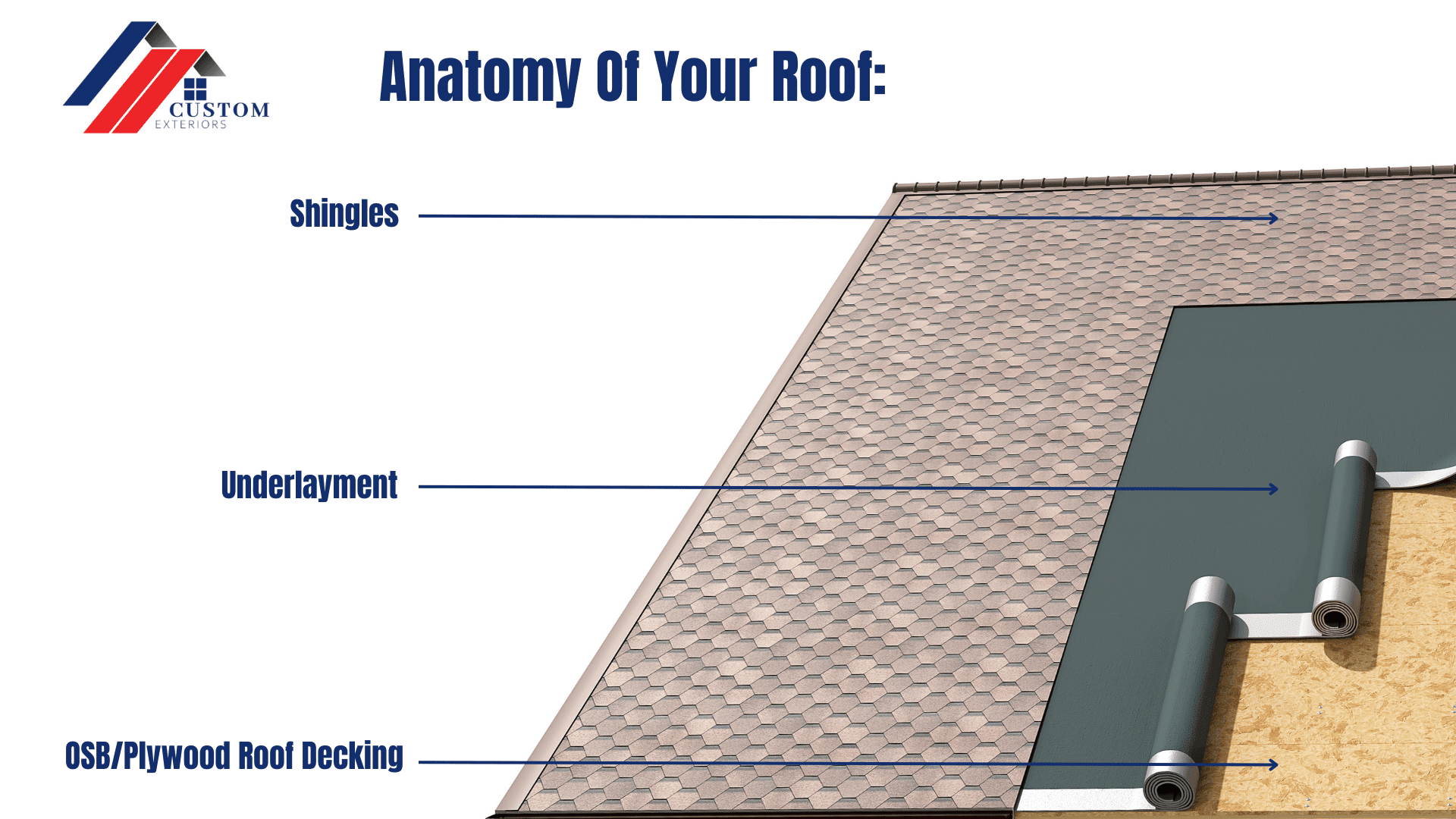

The Foundation your roof: Roof Decking

Every time we replace a roof, the first consideration prior to replacement shingles is the condition of your roof deck. Roof decking is often referred to as sheathing. The roofing decking lays the groundwork for a solid and dependable roof system. The roof deck is the foundation of your system. It must provide structural support and a secure platform for shingles and underlayment.

Modern roof decking is typically made from plywood or oriented strand board (OSB). These materials are chosen for their durability and strength. They have a unique ability to withstand the weight of roofing materials and environmental stressors. Choosing between plywood and OSB may depend on cost, local building codes, and personal preferences.

In older homes, you may discover you have what is called “spaced decking”. Spaced roof decking is wood planks spaced across the rafters of your home forming areas where shingles can be installed. If the spaces exceed one and a half inches, you will likely have to replace your decking with a solid surface prior to your new roof being installed.

In addition to offering structural support, roof decking also protects your home from the elements. It acts as a barrier that helps prevent moisture from entering the interior spaces of your house. Paired with underlayment and shingles, roof decking forms a defense against rain, snow, and wind-driven rain.

roofing Underlayment

Roofing underlayment protects your home from extreme weather and moisture. It’s consistently working behind the scenes. Once you have removed any previous shingle installations and verified the structure of your decking, underlayment is laid on the roof decking. It is a waterproof barrier that covers the entirety of the roof deck under your shingles.

Roofing underlayment is like a safety net. It provides an extra layer of protection beneath your shingles. It’s typically made from asphalt-saturated felt or synthetic materials because those materials guard against moisture. If water gets past your shingles, the underlayment prevents it from seeping into your home.

Local roofing codes enforce the need for underlayment, provide appropriate installation techniques, and determine the thickness required. Qualified roofing contractors will be well versed in the requirements for replacing your asphalt shingle roof.

Asphalt Shingles

Asphalt shingles are a popular choice for roof replacements for many reasons including:

- Asphalt shingles are among the most affordable roofing materials available.

- Compared to other roofing materials, asphalt shingles are relatively easy to install.

- The come in a variety of colors and styles, allowing you to choose the best option for your property.

- While not as long-lasting as some other materials, high-quality asphalt shingles can last 20-30 years.

The top layer of your asphalt shingle roof is the actual shingles. Because of their makeup, asphalt shingles serve as a waterproof barrier for your home. Additionally, they are easy to maintain, can help meet energy-efficiency goals, and provide a beautiful and durable roof on your property.

The Role of roof flashing

When it comes to keeping your home dry, roof flashing plays a vital role that often goes unnoticed. Think of it as your roof’s guide, directing rainwater away from vulnerable areas. This also ensures that moisture stays outside, which is where it belongs!

Roof flashings are usually made of metal. These include metals such as aluminum, copper, or galvanized steel. It aims to provide a watertight seal at points where your roof intersects with other elements, including areas like chimneys, vents, skylights, and walls. By creating a barrier, roof flashing prevents water from entering your home. Thus safeguarding it from potential leaks and water damage.

When rainwater runs down your roof, your flashings direct that water down valleys, away from walls and chimneys, and into your gutter system for drainage away from your property. Your roof flashings are designed to prevent areas of pooling water on your roof.

the importance of roof ventilation

Your roof needs proper ventilation to stay in functional condition. Roof ventilation allows air to circulate. It can also prevent issues that can arise from trapped moisture.

It’s really all about finding the right balance between intake and exhaust. Intake vents allow cool air to enter. In contrast, exhaust vents expel warm, moist air. This cycle ensures that your attic stays at a consistent temperature and humidity level. Doing so prevents excess moisture buildup that can lead to mold, mildew, and even structural damage. Roof ventilation can take various forms, including ridge vents, soffit vents, gable vents, and turbine vents. Each maintains a balanced and healthy attic environment.

Imagine the scorching summer sun beating down on your roof. Without proper ventilation, your attic can become a sweltering furnace. This can potentially damage your roofing materials. It can also increase energy costs. In winter, trapped moisture can freeze. This then leads to ice dams that compromise your roof’s integrity. However, adequate ventilation creates a controlled environment that wards off these potential issues.

The basics of asphalt shingle roof replacement

Over time, your roof will need to be replaced. In some areas, like Colorado, this may be needed more often due to the severe weather we experience. The roof replacement process should be fairly straightforward.

Before the replacement begins, a thorough inspection is conducted to determine the current state of your roof. This step helps identify any underlying issues that need attention, ensuring a smooth transition to your new roof. An inspection by a professional roofer can also verify that you need a roof replacement rather than just a repair. Once that is established, the roof will be measured to determine the amount of shingles, underlayment, and other materials needed for the project. At this time, we also note any areas of concern discovered during the inspection and start preparing for shingle delivery and installation day.

Once the roof has been inspected, estimated, and delivered, the removal of old shingles and damaged components prepares the roof for replacement. The installation process follows a systematic approach. First, a sturdy underlayment is placed, acting as a moisture barrier beneath the shingles.

The drip edge is then installed on the eaves of the roof. This is an essential step as this metal edging is a preventative measure against water seeping up under the shingles at the base of the roof.

.

Layer by Layer

First, your underlayment is placed, covering the roof deck and serving as an additional moisture barrier. If applicable, drip edge is then installed on the eaves of the roof, helping prevent water from seeping under the edge of the underlayment at the base of the roof. Then, the asphalt shingles are installed to form a protective layer against the elements.

Look for a roofing contractor who is skilled and knowledgeable in appropriate placement and nail patterns. The installation will begin with a starter row of shingles. These are installed along the roof’s eaves. These shingles are specially designed to provide a secure base for the rest of the shingles.

The standard shingles are then installed at the roof’s bottom edge. From there, they work their way up to the ridge. Roofing nails are used to secure each shingle in place. The shingles must be cut around roof vents, chimneys, and other obstacles as required.

Once the shingles are installed up to the ridge of the roof, ridge shingles are installed along the roof’s peak. These provide a finished look and also protect against wind damage.

Areas of penetration are then sealed and caulked. This is to help prevent any water intrusion. Upon completing these steps and many more, all debris is cleaned. A reputable roofing company should run magnets to remove any nails or metal in the landscaping. Additionally, they should complete a final roof inspection to ensure it meets local codes.

A professional roofing company can assist with each step, from design to installation!

Safeguarding your investment: roof maintenance essentials

Roof maintenance is an important part of making sure your roof is in working condition and continues to keep your roof safe and dry. The key components of roof maintenance include:

- Regular inspections

- Clean gutters and downspouts

- Remove debris

- Trim overhanging tree branches

- Check for moss or organic growth

- Inspect and repair sealant and flashing

- Look for signs of rust on metal parts

- Repair damaged shingles

- Check for interior water damage

Occasionally, it’s a good idea to have a professional roofing contractor inspect your roof. They can identify potential issues that you might miss and provide expert maintenance or repair advice. Regular and thorough maintenance can extend the life of your roof, improve your home’s energy efficiency, and prevent costly repairs in the future.

The financial wisdom of roof maintenance

While it’s easy to overlook, regular roof maintenance isn’t just about preventing leaks. It’s also a smart financial move. Investing in routine maintenance can save significant amounts in the long run. Minor maintenance issues can quickly become costly repairs, and by maintaining your roof, you can often save on more major repair projects down the line.

"Depending on the type of repair, roof repair costs can run anywhere from $150 to $400 for minor repairs and up to $8,000 for major repairs." ~Forbes

Your roof’s lifespan can be extended through proper care. A well-maintained roof is less likely to suffer from premature deterioration, ensuring that you get the most out of your investment. With regular inspections, cleaning, and minor repairs, you can enjoy a roof that stands strong for years to come.

Maintaining your roof long term

Your roof is an important part of your exterior. Not only is it a huge part of your home’s exterior curb appeal, but it also provides protection from the harsh elements your home faces. From asphalt shingles to underlayment, from flashing to ventilation. Each component ensures your home’s protection, comfort, and style. As seasons change and time passes, your roof protects against the elements.

At Custom Exteriors, we’re more than a roofing company – we’re also your partner in maintaining the integrity and beauty of your home. From installation to maintenance, we bring expertise and dedication to every step of the process. So, whether you’re considering a roof replacement, exploring ventilation options, or seeking a trusted partner for routine maintenance, we’re here to ensure your roof remains a source of pride for years.

Contact Us Today

We Service and Support the Following Brands

Contact

Custom Exteriors, LLC

2881 S. 31st Ave, Greeley, CO 80631

109 E. 17th St. Ste 5822, Cheyenne, WY 82001

102 S. Tejon St. Ste 1100, Colorado Springs, CO 80903

404 Broadway, Eagle CO 81631

Phone: 970-460-8714

Toll Free: 800-580-0131

Quick Links

© 2022 Custom Exteriors, LLC