- Custom Exteriors

- March 30, 2023

Everything you need to know about your EPDM Roof

If you have an EPDM (Ethylene Propylene Diene Monomer) roof, you know what a dependable choice it is for a commercial roof replacement. As a commercial roofing contractor, we have seen firsthand how the right (or wrong) roofing can significantly impact a building’s integrity, energy efficiency, and overall maintenance costs.

EPDM roofing is known for its remarkable ability to withstand extreme weather conditions, making it a great choice in Colorado, which is prone to severe weather. Its long lifespan and minimal maintenance requirements make it attractive to building owners and property managers looking to maximize their investment.

In the following sections, we’ll explore everything from the basics of EPDM roofing and its advantages to installation processes, maintenance tips, and cost considerations. So, whether you are looking to replace an old roof or are constructing a new building, our goal is to equip you with the knowledge to choose a roofing system that meets your needs and your budget. With EPDM roofing, many have found a reliable solution that stands the test of time while also being gentle on the budget.

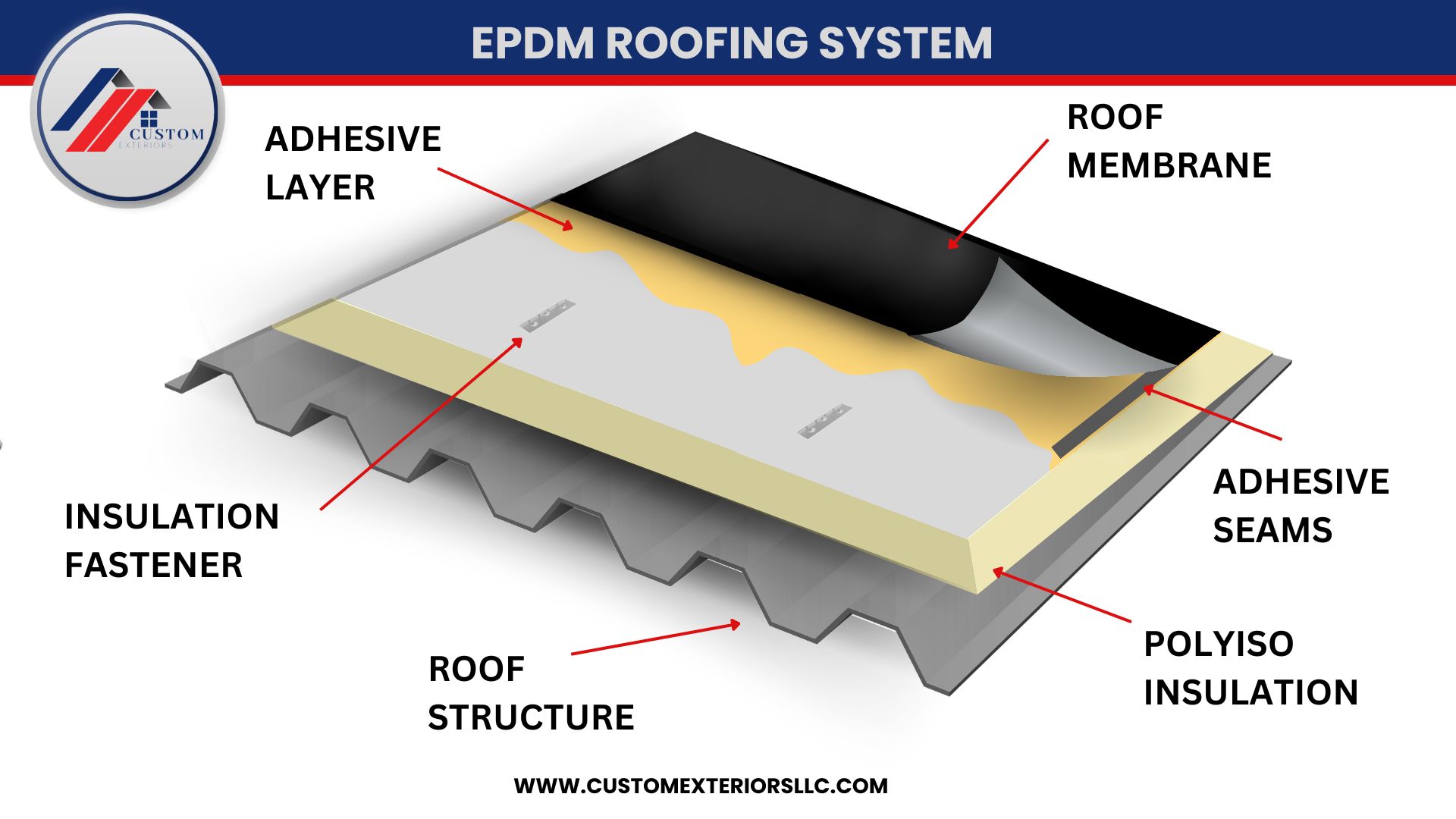

What is EPDM roofing?

EPDM roofing is made from a synthetic rubber called Ethylene Propylene Diene Monomer. These roofing systems are a popular choice for low-slope/flat roofs. EPDM roofing systems are highly durable and can last up to 50 years or more with proper maintenance. Because of their makeup, they are very resistant to UV radiation, weathering, ozone, and other environmental factors that can cause damage to other roofing materials, such as asphalt shingles.

EPDM roofing systems are relatively easy to install and require minimal maintenance, making them an extremely cost-practical choice for flat roof systems. They can be used on various roofs, including flat and low slopes, and are available in multiple thicknesses and colors to suit different design requirements.

Because EPDM roofing systems are highly reflective, they can help keep buildings cooler in hot weather and reduce energy costs. This type of roofing system is also a recyclable material and does not release harmful chemicals into the environment during installation or use. Your local roofing contractor can tell you if an EPDM roof is a good fit for your property.

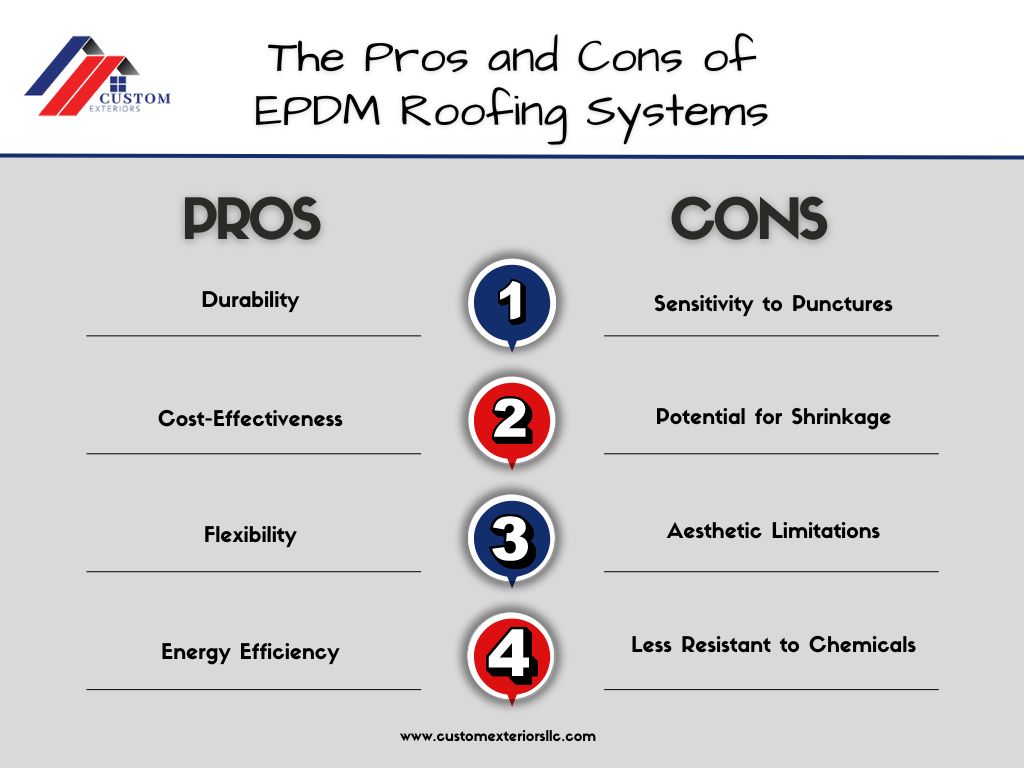

The Pros and Cons of EPDM roofing

EPDM roofing is a standout option for commercial buildings. Its benefits make it a common choice for commercial roof replacements in our area. However, like any roofing system, it has its own set of limitations that might impact its performance on your property.

Advantages of EPDM roofing

- Durability: EPDM roofs are built to last, often serving well for over 20 years with proper care. This durability stems from the material’s resistance to weather, including harsh sunlight, heavy rain, and even snow, ensuring your building stays protected year-round.

- Cost Effectiveness: EPDM is more affordable than other roofing materials in terms of initial costs and long-term maintenance. Its ease of installation further reduces labor costs, making it an economically wise choice for large commercial roofs.

- Flexibility: EPDM is known to be flexible in cold weather, which makes it appealing to Colorado property owners. Unlike some materials that can become brittle and crack in low temperatures, EPDM remains flexible, reducing the risk of damage during colder months.

- Energy Efficiency: EPDM has high heat-reflective properties, especially with lighter-colored membranes. This can lead to lower cooling costs in the warmer months, contributing to a more energy-efficient building overall.

disadvantages and considerations

- Sensitivity to Punctures: Though durable to weather, EPDM can be punctured by sharp objects. Regular inspections and immediate repair of any damage are crucial to prevent leaks.

- Potential for Shrinkage: While not common in properly installed EPDM roofs, shrinkage can occur, potentially affecting the roof’s integrity. Choosing a reputable contractor for installation and performing regular maintenance can mitigate this risk.

- Aesthetic Limitations: EPDM typically comes in black or white, which may not suit all architectural styles. Because its appearance is simple and functional, those looking for more color or texture options might find EPDM’s choices limiting.

- Comparative Analysis with Other Materials: While EPDM excels in many areas, there are scenarios where other materials may offer benefits that better align with your property’s needs. For example, TPO and PVC roofing, other types of single-ply membranes, offer different advantages in terms of reflectivity and chemical resistance.

It’s important to consider your property’s specific needs and the climate and environmental factors it faces. EPDM roofing is a durable, cost-effective option for commercial properties looking for a long lifespan with low maintenance needs. However, as with any significant decision, weighing these factors carefully will help you choose the best system for your commercial roof replacement.

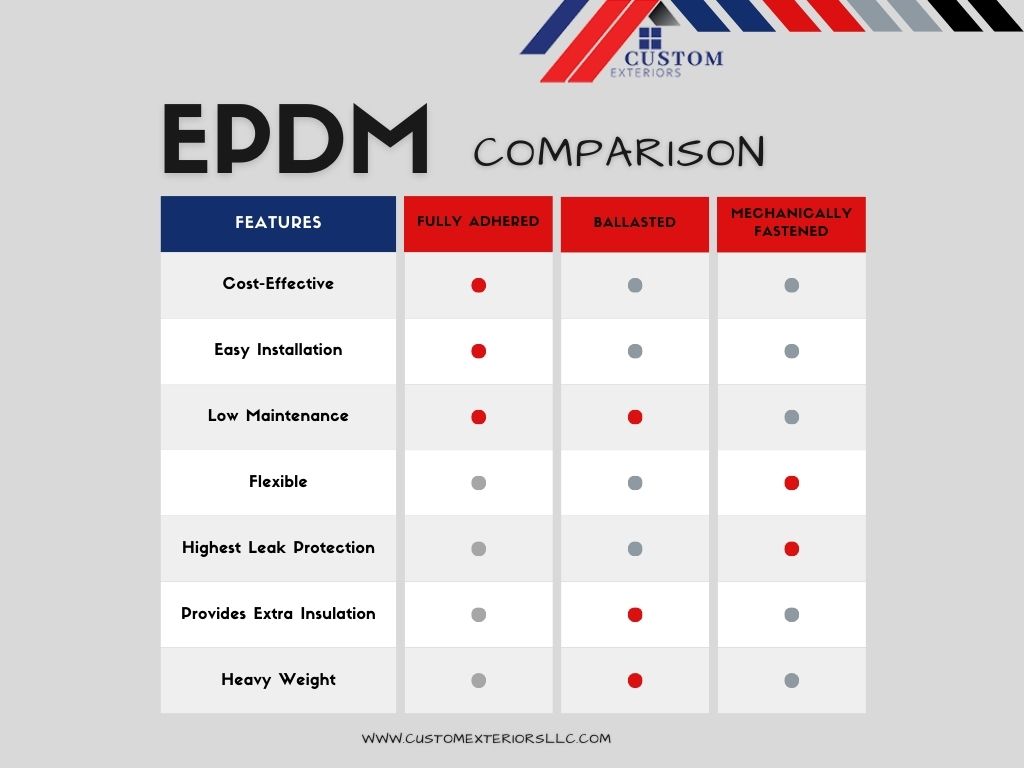

Types of EPDM Roofs

Fully Adhered EPDM Roofs

In this EPDM roof system, the EPDM membrane is adhered to the roof substrate using a specially formulated adhesive. It provides a strong bond between the EPDM and the substrate, making it ideal for roofs with complex shapes or curved surfaces. Fully adhered EPDM roofs can be more expensive to install than Mechanically Fastened or Ballasted EPDM roofs.

Again the roof deck must be cleaned and have existing roofing material removed. After this, a specially formulated adhesive is applied to the roof substrate using a trowel or sprayer. The EPDM membrane is then rolled out onto the roof deck and carefully positioned to overlap the adhesive layer. The membrane is then smoothed out to ensure good contact with the adhesive.

Once the EPDM membrane is attached to the deck, the seams are sealed using adhesive or specialized tape, preventing water intrusion. Lastly, flashing around all roof penetrations prevents water from entering the building.

Ballasted EPDM Roofs

Ballasted EPDM roofs use a ballast layer to hold the EPDM membrane in place. This is the most economical and straightforward method of installation. It is ideal for roofs with low slopes or no slope conditions.

Unfortunately, if damage occurs, ballasted EPDM roofs can be more challenging to repair. The ballast layer must be removed prior to repair, which can be time-consuming and labor-intensive.

Once the roof deck is thoroughly cleaned, a layer of insulation is installed on top of the roof deck. The EPDM membrane is rolled onto the deck and cut to size. After it has been positioned, a ballast layer is applied on top of the EPDM membrane to hold it in place. This ballast can be gravel or pavers and typically ranges from 1.5 to 3 inches thick. Like the other systems, seams must be sealed, and penetrations flashed to prevent water intrusion. The ballast can also protect against hail damage and other effects of extreme weather.

Mechanically Fastened EPDM Roofs

This type of EPDM roof system is installed by mechanically fastening the EPDM membrane to the roof deck using special fasteners and plates. This application is handy in high-wind or uplift locations, providing a secure attachment.

First, the roof deck must be cleaned and any existing roofing materials removed. Then, a layer of insulation is installed on top of the roof deck. This provides thermal resistance and improves energy efficiency. The EPDM membrane is then rolled onto the roof deck and cut to size. Mechanical fasteners are placed along the edges of the membrane and in the field at specific intervals to ensure the membrane is securely attached.

Once the EPDM membrane is attached, your commercial roofer will seal the seams with adhesive or specialized tape to prevent water from penetrating the roof system. Lastly, flashing is installed around roof penetrations, including vents, pipes, and skylights.

EPDM Roofing maintenance 101: Protecting your investment

If our experience has taught us one thing in commercial roofing, it is the fact that maintaining and repairing your EPDM roof is directly related to its lifespan and the protection it provides for your property. Regular upkeep not only extends the life of your roof but also helps prevent minor issues from becoming major, costly problems.

Owners and property managers who take a reactive approach to roof maintenance spend an average of .25¢ per square foot per year on maintenance-related issues. On the other hand, those who take a proactive approach spend an average of only .14¢. ~Buildings.com

Regular maintenance

The average replacement cost of an EPDM roof ranges between $4.00 and $15.00 per square foot, so a commercial roof replacement can be expensive. However, there are some important reminders about exterior maintenance that you may not be aware of.

- Studies show up to 80% of roofs have to be replaced prematurely.

- Roof maintenance programs are tax deductible, improving your business's bottom line.

- A leaking roof can be actively leaking for months before outward signs become visible. By then repairs will likely be costly.

- Roof maintenance programs can save you up to 50% over the life of the roof with extended lifespan.

- Regular roof maintenance can prevent leaks that can cause interuptions to your operations.

Whether you choose a structured maintenance plan or do your own commercial roof maintenance, in order to keep your EPDM roof in top condition, the following maintenance tasks should be conducted bi-annually.

EPDM maintenance tasks

- Inspections: Conduct thorough inspections of your EPDM roof at least twice a year and after major weather events such as hail or high winds. Look for signs of wear, such as cracks, punctures, or areas where the membrane might have pulled away from the edges of the roof. While we recommend bi-annual inspections, additional inspections completed after severe weather will help to catch any possible damage caused by the storm quickly. By addressing minor issues immediately, you prevent some major issues that can be caused by roof leaks, such as mold and interior damage.

- Cleaning: Keep the roof surface clean from debris, dirt, and leaves. A clean roof allows for proper drainage and prevents water from pooling (a common cause of roof damage over time.) Use a soft-bristles brush and a gentle cleaning solution if needed to avoid damaging the membrane. Remember, an EPDM roof is less resistant to some chemicals than other roofing systems. Avoid using harsh cleaning agents or damaging tools when cleaning.

- Drainage: Ensure that your roof’s drainage system is working correctly. Whether your building utilizes roof drains or a traditional gutter system, regularly clean out gutters, downspouts, and drains to prevent blockages. Proper drainage reduces the risk of water accumulation that can lead to leaks and other water-related damage.

- Immediate Repairs: During your inspections, address small issues, such as minor punctures or seams starting to come apart, immediately. Small, proactive repairs can prevent larger issues and help maintain the roof’s integrity.

By quickly addressing any issues found during inspections, you can significantly extend the life of your EPDM roofing system. In doing so, you ensure it continues to provide reliable protection for your commercial property. Regular, attentive care allows you to maximize the investment you made in your roof and avoid unexpected issues that could disrupt your business. The most common signs you need to call in a commercial roof are:

- Punctures

- Tears or Holes in Seams

- Pooling Water

Choose an EPDM Roofing Systems For Your Flat Roof

If you are replacing the roof on your commercial building and considering EPDM, choosing the right system is crucial. This choice will impact not just the roof’s performance but also the overall maintenance needs of your building. Your choice can also significantly impact the building’s energy efficiency and costs over time.

Understanding your buildings requirements

- Consider the weight your roof can support. Ballasted systems are heavier, so for some structures, a fully adhered or mechanically attached system might be better.

- Areas with strong winds or frequent storms require a roofing system with a higher wind uplift resistance, making a fully adhered system a good choice.

- If your roof will have a lot of foot traffic, durability becomes an important factor. In this case, a fully adhered system might be the right choice again.

Just as important as the roofing system, it is important to choose a commercial roofing contractor with experience in installing the specific system you are considering. They will be able to provide you with the pros and cons of the system you are considering, making your decision easier. Check their references and reviews.

Choosing the right EPDM roofing system involves carefully considering your building’s needs, the specific advantages and drawbacks of each system, and selecting a qualified contractor. By taking these steps, you ensure that your building is equipped with a roofing system that not only meets your immediate needs but also serves as a long-term asset.

In summary, EPDM roofing system offers a range of benefits. They are highly durable and can last up to 50 years with proper installation and maintenance. EPDM roofs are highly flexible and can adapt to changes in temperature and weather conditions without cracking or deteriorating. Because of this, they are not prone to water leakage.

EPDM roofing systems are highly reflective, making them exceptionally energy efficient. They are made from a recyclable synthetic rubber material, so they are also an environmentally friendly choice.

The installation process for mechanically fastened, fully adhered, and ballasted roofing systems are relatively straightforward. Because of this, property owners can save both time and money! Additionally, once installed, they require minimal long-term maintenance. Occasional inspections and repairs are required to keep them in good condition.

To learn more about EPDM roofing systems, the ERA provides more detailed information. To discuss roof replacement using an EPDM roofing system, contact us today!

Contact Us Today

We Service and Support the Following Brands

Contact

Custom Exteriors, LLC

18674 Co Rd 3, Berthoud, CO 80513

109 E. 17th St. Ste 5822, Cheyenne, WY 82001

102 S. Tejon St. Ste 1100, Colorado Springs, CO 80903

404 Broadway, Eagle CO 81631

Phone: 970-460-8714

Toll Free: 800-580-0131

Quick Links

© 2022 Custom Exteriors, LLC