What is a PVC Roofing System?

What is PVC Roofing?

PVC roofing is a type of roofing material made from Polyvinyl Chloride (PVC). It is a thermoplastic material that is durable, lightweight, and resistant to weathering, fire, and chemicals. While it is most often used for commercial and industrial buildings, it can also be found in residential applications.

PVC roofing comes in many forms, including sheets, membranes, and panels, and is available in various colors and textures. It is typically installed using hot air welding, which fuses the seams and creates a weather-tight seal. It is easy to maintain and can last for many years with proper roof maintenance.

One of the main advantages of PVC roofing is its energy efficiency. PVC roof systems reflect a significant amount of heat and light, thus reducing cooling costs and making the building more comfortable in hot weather. Additionally, PVC roofing systems are often made from recycled materials and can be recycled at the end of their useful life, making them an environmentally friendly option.

How is PVC Roofing Made?

PVC roofing systems are manufactured using a process called extrusion. Here are the basic steps involved:

- Mixing: First, raw materials are mixed together in a large mixer. The materials include PVC resin, plasticizers, stabilizers, and other additives.

- Extrusion: the mixed materials are then fed into an extruder, which heats and melts them into a uniform liquid. The liquid is then forced through a die that shapes it into a continuous sheet of PVC roofing material.

- Cooling: As the PVC sheet emerges from the die, it passes through a series of cooling rollers that gradually bring it down to room temperature. This helps ensure it maintains its desired shape and properties.

- Cutting and finishing: Once the PVC sheet has been cooled, it is cut into the desired length and shape.

Overall, the process of manufacturing PVC roofing systems is automated and can be done on a large scale. Because of this, it is a cost-effective and efficient choice for many roofing applications.

Types of PVC Roofing

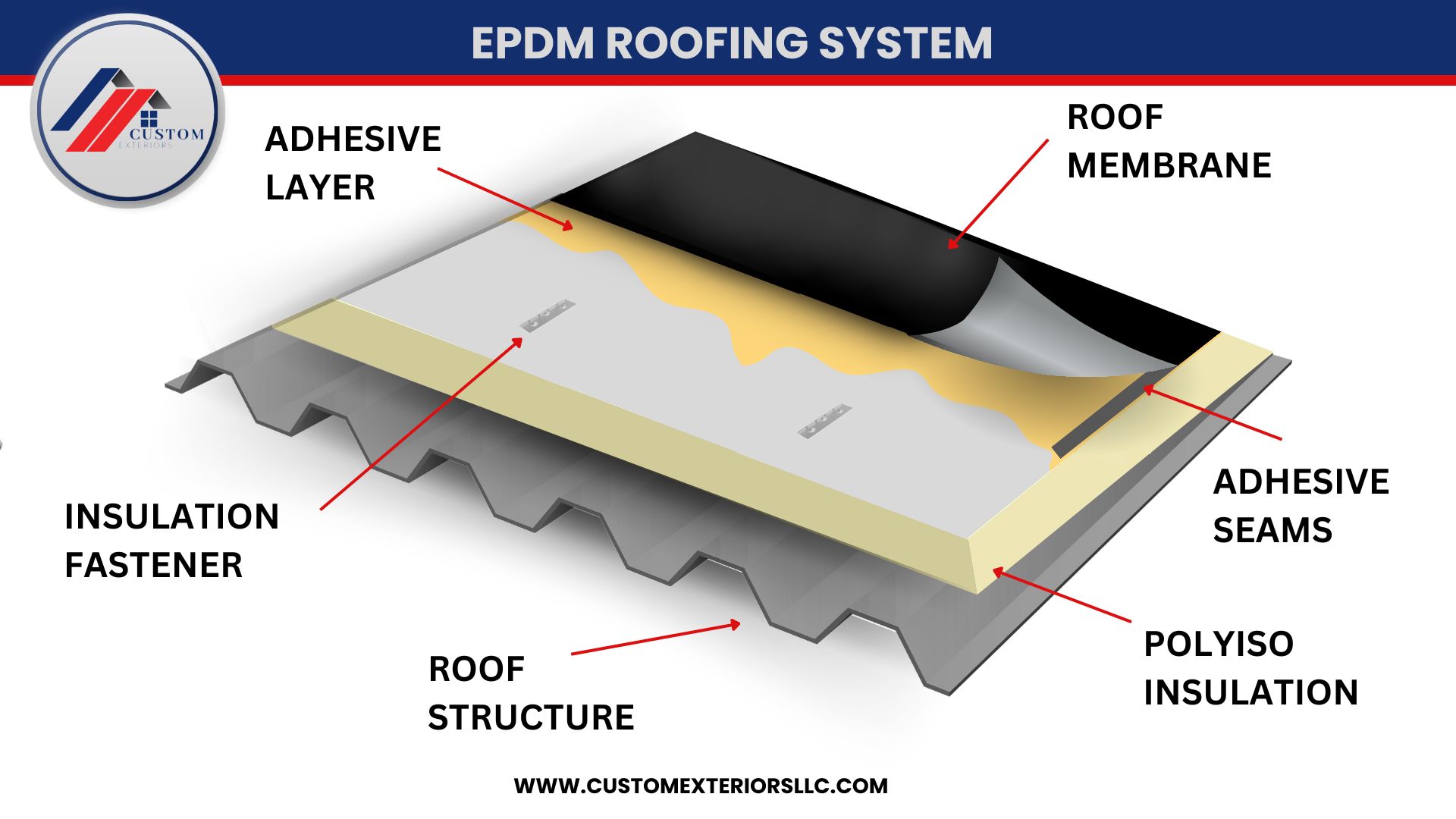

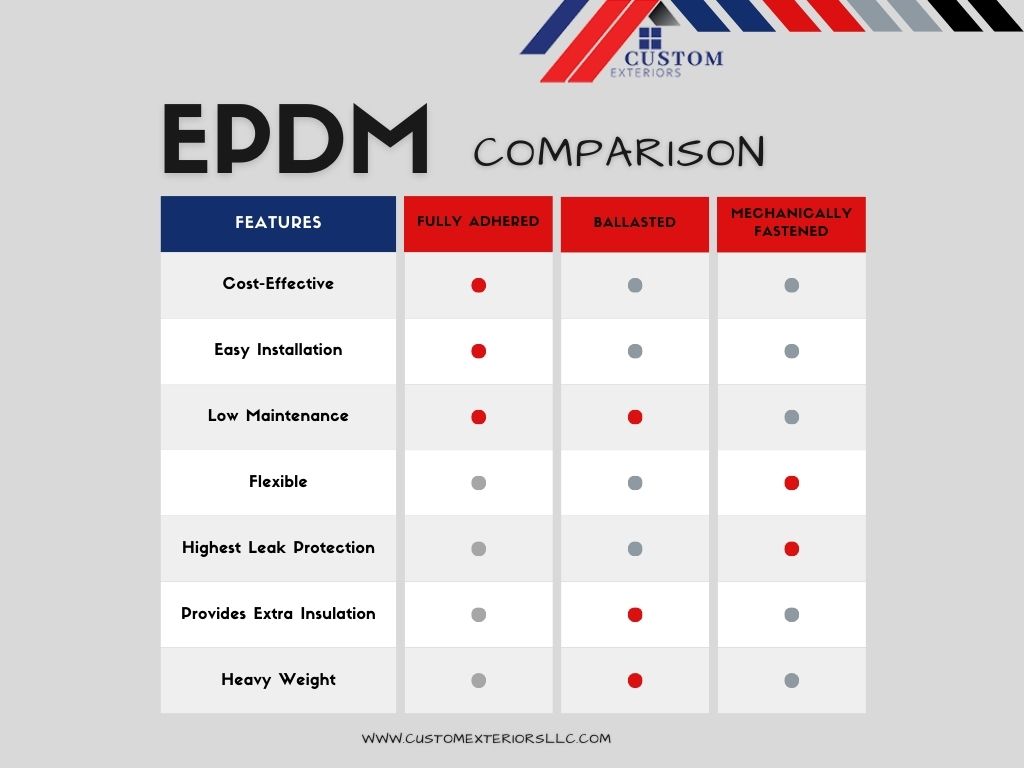

There are multiple types of PVC roofing systems available. Some of the most common types of PVC roofing systems include single-py PVC roofing, mechanically attached PVC roofing, fully adhered PVC roofing, and ballasted PVC roofing.

The single-ply PVC roofing is the most common type. It involves installing a single layer of PVC roofing membrane over the roof deck. The membrane is typically reinforced with polyester or fiberglass to improve its strength and durability. Mechanically attached PVC roofing systems attached the PVC to the roof deck using fasteners. It is faster and easier than hot air welding but can be less watertight and may require more maintenance over time. Fully adhered PVC roofing bonds the PVC membrane to the roof deck. It provides the most robust and watertight seal but is more expensive and time-consuming to install. Lastly, ballasted PVC uses gravel or pavers to hold the membrane. It is less costly and provides excellent insulation, but it can be more challenging to repair if damage occurs.

The best type of PVC roofing for your property will depend on factors such as the size and slope of the roof, the weather conditions in your area, and the desired level of insulation and energy efficiency. Your local roofing expert can help discuss these options to ensure the proper fit for your property.

Benefits of PVC Roofing Systems

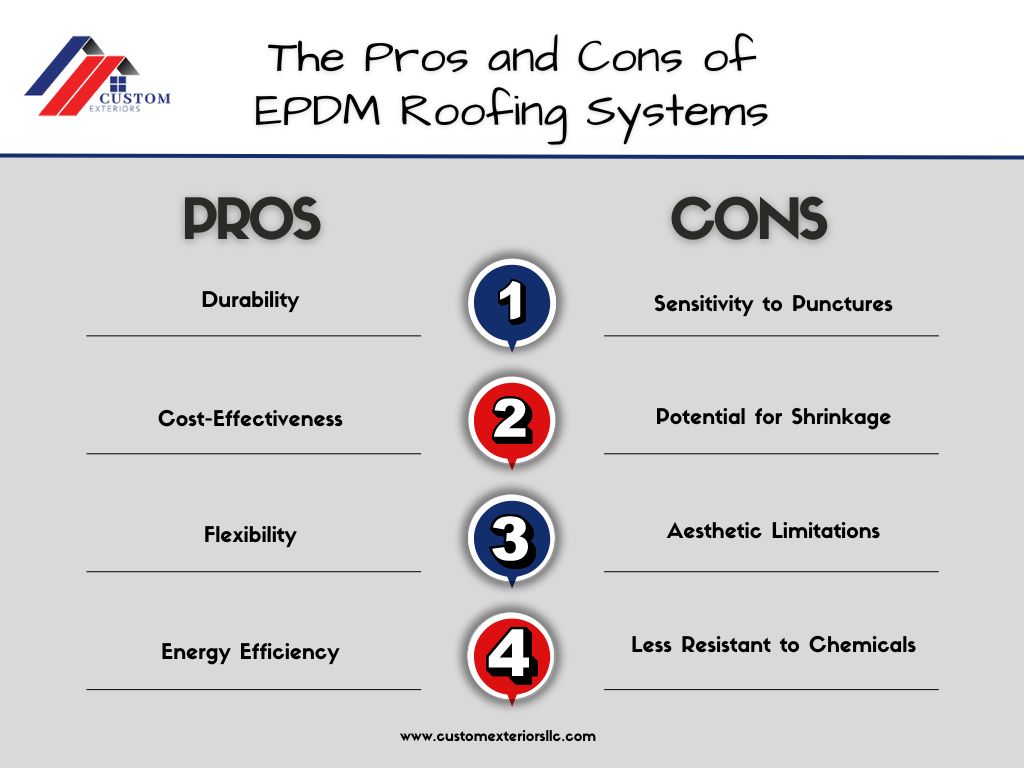

PVC roofing systems offer several benefits over other roofing systems. Some of the main advantages include the following:

- Durability: PVC roofing systems are highly durable. They can withstand harsh weather conditions, including wind, rain, snow, and hail. This can benefit areas prone to severe weather, such as Colorado and Wyoming. It is also resistant to fire and chemicals, making it a good choice for industrial and commercial applications.

- Energy Efficiency: PVC roofing systems are highly reflective. This can provide good insulation and help reduce both heating and cooling costs.

- Easy Maintenance: PVC roofing systems are easy to maintain and require minimal upkeep. It is resistant to mold, mildew, and algae growth, thus keeping the roof clean and debris-free.

- Long Lifespan: PVC roofing systems can last up to 30 years or more with proper installation and maintenance.

- Environmentally Friendly: PVC roofing systems are often made from recycled material and can be recycled at the end of their useful life. Because of this, it helps lower the building’s carbon footprint.

PVC Roofing Systems for Your Flat Roof

PVC roofing systems can be a good choice for many applications, but whether or not it is the best choice will depend on various factors, such as the climate and weather conditions, the size and slope of the roof, and the building’s intended use. A qualified flat roofing contractor will be able to walk you through the options best suited for your facility.

While PVC roofing provides many benefits, such as energy efficiency, durability, low maintenance, and a long lifespan, some factors must be considered to determine if a PVC roofing system is right for you. For example, PVC roofing systems can be more expensive than other roofing materials and may not be suitable for roofs with steep slopes or complex shapes. Choosing a reputable manufacturer and installer is also essential to ensure the PVC roofing system is installed correctly and will perform as expected over its lifespan.

If your roof has a pitch of lower than 2:12, it is considered a low slope. Because of this downward slope, water does not drain off the roof’s surface as it would in a high-pitch design. Asphalt shingles are not designed to handle standing water, so that a PVC roofing system may be a good fit for your low-slope roof design.

With decades of experience, Custom Exteriors has provided Colorado property owners with high-quality flat roof solutions. You can count on us to help you design a functional flat roofing system that will protect your building for years to come!